Time:2023-05-18 Reading:2219

Raw material source analysis

Butyrolactam is the monomer for the synthesis of Polyamide 4, and its basic properties are as follows, with a melting point of 23 ~ 25 ° C (24.6 ° C). Boiling point 245℃, 133℃ (1.6kPa). The relative density is 1.12. Refractive index 1.48, can soluble in water and most organic solvents, but insoluble in petroleum, form a monohydrate in wet air (boiling point 35℃). Butyrolactam is chemical stability, non-corrosive, irritating to eyes, skin and mucous membranes. Adequate raw material source is the first condition for the industrialization of Polyamide 4, butyrolactam is the main monomer for the preparation of Polyamide 4, its reliable source will be the basis of the industrialization of Polyamide 4. According to the source of carbon in the butyrolactam molecule, the source is mainly bio-based and petroleum-based.

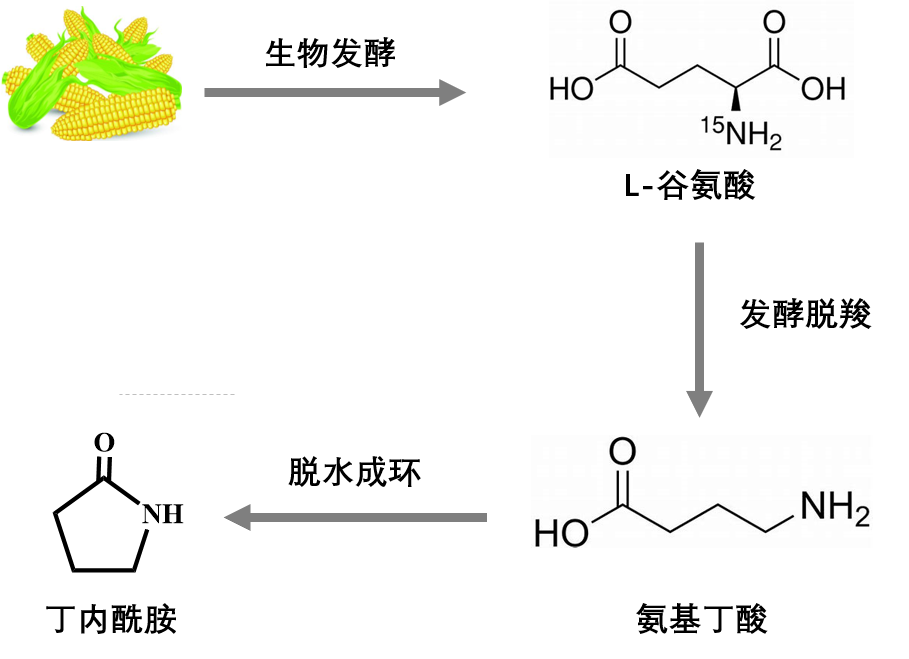

The bio-based source is mainly glutamic acid obtained from biomass through biological fermentation or protein hydrolysis, and then Escherichia coli is used as a strain. The function of Escherichia coli Chemicalbook decarboxylase is used to convert L-glutamic acid into γ-aminobutyric acid which can be dissociated into cations in aqueous solution. The finished product is obtained by ion exchange with strong acid styrene cation exchange resin, elution with ammonia, extraction, purification by resin, concentration, crystallization and drying.

FIG. 1 Biobutyl lactam synthesis process

Bio-based butyrolactam is produced by biomass fermentation, independent of fossil raw materials. Currently, the price of glutamic acid is about 19,000-25,000 / ton, and only from the perspective of atomic conservation, the price of bio-based butyrolactam is 33-43,000 / ton. The cost and conversion rate of glutamic acid fermentation decarboxylation into GABA aminobutyric acid as well as the dehydration of aminobutyric acid are combined. The price of bio-based butyrolactam lactam will be further increased, which will greatly limit the promotion of the industrialization of Polyamide 4. In addition, the large-scale use of biomass synthesis monomer will not only produce a large amount of wastewater in the fermentation process, but also have the potential problem of competing with people for food, and its industrial scale will be greatly limited. This is also the main reason why the current capacity expansion of polylactic acid cannot be compared with petroleum-based degradable materials such as PBAT and PBS.

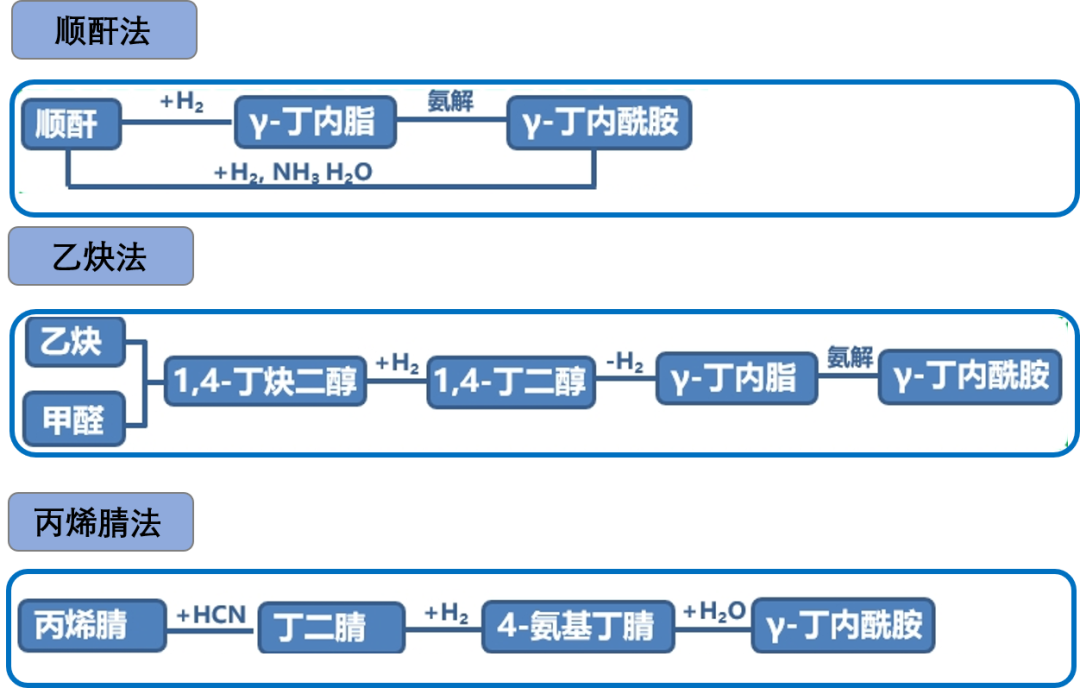

Petroleum-based butyrolactam is obtained from petroleum-based chemicals by various chemical reactions. At present, only through the following three ways, the most important is through the maleic anhydride method, taking maleic anhydride as the raw material, a step of hydrogenation to get γ-butylactone and then further ammonolysis to get butyrolactam. The price of butyrolactam synthesized by this way can be 15,000 / ton, which is very competitive compared with the current monomer price of degradable materials.

FIG. 2 Synthesis process of petroleum-based butyrolactam

The preparation of butyrolactam by petroleum base can provide sufficient and stable raw material source for the industrialization of Polyamide 4, and the raw material used is the basic chemical, the integration of raw material is more convenient. Therefore, in the large closed loop of industrial integration of Poltamide 4, the raw material source should be dominated by petroleum-based sources, and bio-based sources can be supplemented.

Shanghai Institute of Cleantech Innovation, in maleic anhydride hydrogenation to prepare γ-butyrolactone and further ammonolysis to prepare γ- butyrolactam hydrogenation catalyst preparation and monomer synthesis process and the corresponding engineering amplification has profound technical accumulation, welcome to exchange and discuss.