Time:2020-07-10 Reading:11020

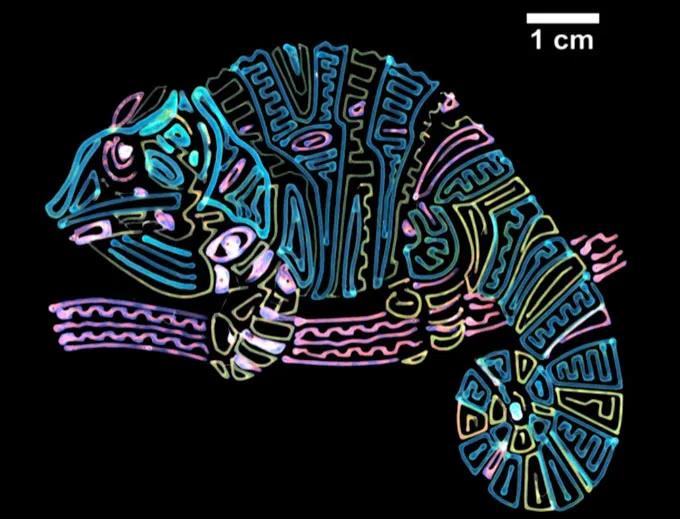

Similar to

colorful flowers, butterflies, chameleons, and other animals often display vibrant

colors, although there are differences between these two phenomena. The colors

of flowers mainly come from pigments, where pigments absorb or reflect specific

wavelengths of light to produce colors. On the other hand, the colors of

butterflies or chameleons originate from subtle structures on their bodies,

such as nano "photonic crystals" (PC), which involve light

scattering, diffraction, and interference. This phenomenon is known as

"structural color." Structural color offers various advantages, such

as resistance to fading, water washing, and adjustable colors. However,

achieving structural color conveniently and efficiently through currently

popular 3D printing technology is still not feasible.

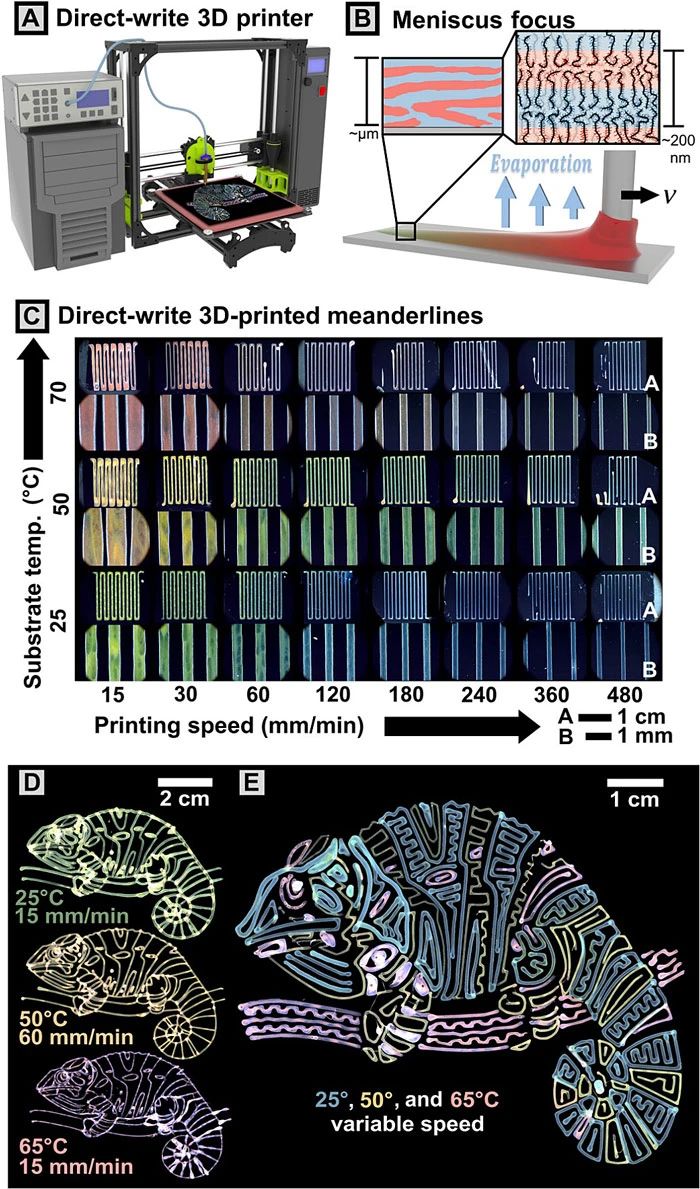

Recently, the research group led by Ying Diao at the University of Illinois Urbana-Champaign (UIUC) in the United States published a paper in the journal Science Advances, demonstrating the 3D printing of vibrant structural colors using only one type of "ink." The crucial aspect of this work lies in the use of a polymer material known as "bottlebrush copolymer" in their "ink."

3D printing of

a colorful chameleon image. Image

source: Sci. Adv.

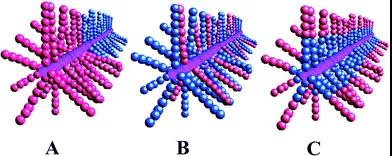

"Bottlebrush

copolymer" is a type of branched or grafted polymer with high grafting

density side chains attached to the main chain backbone, resembling the shape

of a bottlebrush. Due to its unique structure, it can form complex but highly

ordered materials. By controlling the selection of monomers and the synthesis

process, it allows for the design and fabrication of "DIY nanomaterials"

with specific size, shape, and composition. As a result, it has broad research

and application potential in various fields, such as surfactants, photonic

crystals, coatings, and nanomedicine.

Schematic

diagrams of three "bottlebrush copolymers." Image source: Chem. Soc. Rev. [1]

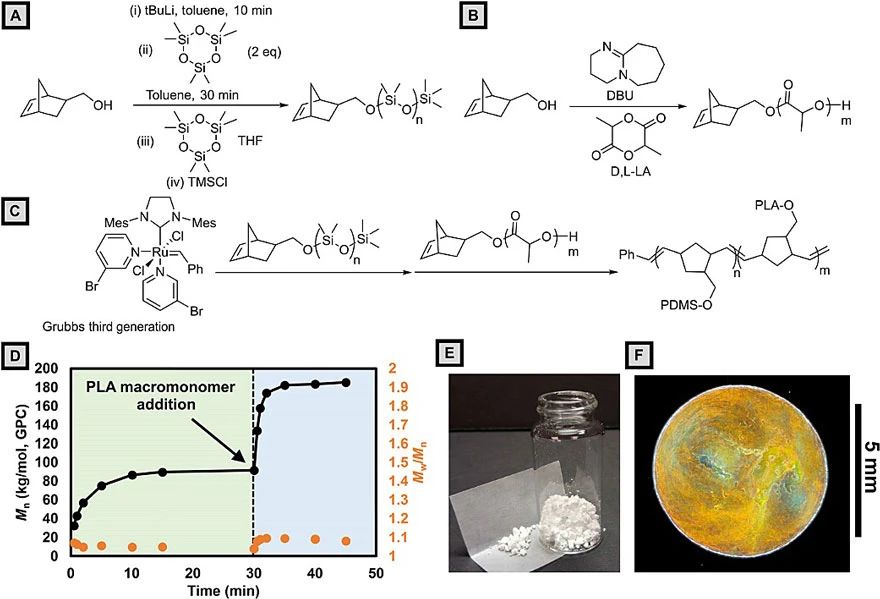

The researchers

used ring-opening metathesis polymerization (ROMP) to synthesize

bottlebrush-shaped graft copolymers PDMS-b-PLA. In this copolymer,

polydimethylsiloxane (PDMS) and polylactic acid (PLA) each accounted for 50% of

the composition, and gel permeation chromatography (GPC) analysis showed a

narrow molecular weight distribution.

Preparation of

PDMS-b-PLA bottlebrush copolymer. Image

source: Sci. Adv.

The copolymer

white solid powder (Figure E) was dissolved in tetrahydrofuran (THF) to prepare

a solution with a concentration of 100 mg/mL, which served as the required

"ink" for printing. In the solution, the branched chains of the

bottlebrush polymer entangled with each other, forming micelles. When the

solution was drop-cast to form a film, the solvent evaporated, causing

microphase separation between polymer molecules, resulting in an ordered

layered structure and leading to significant random colors.

“Colorful thin films formed after drying the 'bottlebrush copolymer' solution”. Image source: Sci. Adv.

The bottlebrush

copolymer can exhibit a wide range of vibrant colors, which can be controlled

by adjusting the printing speed, applied pressure, and substrate temperature.

In other words, these factors influence the polymer's microphase separation

process. The researchers loaded the 'ink' into a 3D printer and, under a

pressure of 30 kPa, obtained a two-dimensional color matrix by varying the

substrate temperature (25 °C, 50 °C, and 70 °C) and printing speed (15 to 480

mm/min). The printed lines displayed consistent colors. However, slight color

variations were observed at the beginning of printing and around corners

(Figure C)."

3D printing

complex structural colors. Image

source: Sci. Adv.

The 3D printed

structural colors exhibit a wide range, ranging from blue light at 403 nm to

red light at 626 nm. By programming the 3D printer, more intricate patterns can

be achieved. The researchers printed three different-colored chameleons (Figure

D) and a chameleon with three colors on a silicon wafer by adjusting the

printing speed, pressure (35 kPa), and temperature (Figure E).

3D printing

complex structural color patterns.

Image source: Sci. Adv.

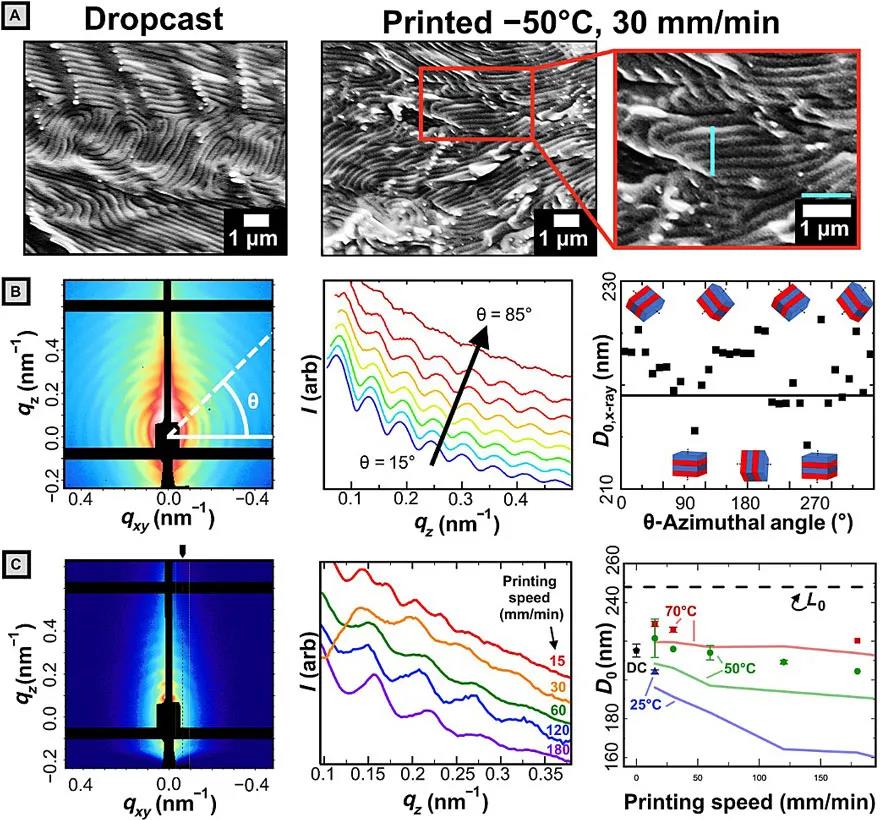

With the

increase in printing speed, a significant blue shift in the reflected

wavelength is observed, while higher temperatures cause a noticeable red shift.

Through SEM and SAXS characterization, the color variations result from the

different domain spacings in the printed layered thin films. The changes in

domain spacing are attributed to the "head-to-head" arrangement of

the bottlebrush copolymer molecules, meaning that each structural unit consists

of a double layer, and the layer backbone exhibits significant elasticity. The

variation in domain spacing is caused by the expansion and compression of the

molecules.

Microscopic

structural characterization. Image

source: Sci. Adv.

"Utilizing

polymers to achieve these vivid colors and applying them in eco-friendly

coatings and highly selective optical filters pose a challenge," says Ying

Diao. "Accurate control of polymer synthesis and processing is required to

form ultra-thin ordered structures, creating structural colors observed in the

natural world." Currently, the colors obtained through this method are

still limited and not well-suited for large-scale printing. Therefore, "we

are collaborating with Damien Guironnet, Charles Sing, and Simon Rogers from

the American Institute of Chemical Engineers to develop more easily

controllable polymers and printing processes, bringing us closer to producing

vivid colors found in nature." [2]

Tunable

structural color of bottlebrush block copolymers through direct-write 3D

printing from solution

Bijal B. Patel,

Dylan J. Walsh, Do Hoon Kim, Justin Kwok, Byeongdu Lee, Damien Guironnet, Ying

Diao

Sci. Adv.,

2020, DOI: 10.1126/sciadv.aaz7202

References:

1. Verduzco R,

Li X, Pesek S L, et al. Structure, function, self-assembly, and applications of

bottlebrush copolymers. Chem. Soc. Rev., 2015, 44, 2405-2420.

https://pubs.rsc.org/en/content/articlelanding/2015/cs/c4cs00329b#!divAbstract

2. Researchers

mimic nature for fast, colorful 3D printing

https://news.illinois.edu/view/6367/809468

The article is

transferred from the WeChat public account "X-MOL Information"