Time:2020-11-11 Reading:12279

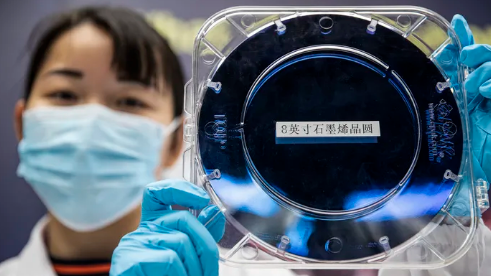

On October 16th, the 2020 China

International Graphene Innovation Conference was held, where new materials such

as ultra-flat copper-nickel alloy single-crystal wafers, 8-inch graphene

single-crystal wafers, and germanium-based graphene wafers were unveiled,

showcasing China's innovative achievements in high-quality graphene materials.

Driven by the Shanghai Graphene Industry Technology Functional Platform, the

research team has achieved small-batch production of these achievements,

leading internationally in terms of product size and quality.

In 2009, the research team from the

Shanghai Institute of Microsystem and Information Technology, Chinese Academy

of Sciences, targeted the key issues in the preparation of graphene single

crystals and their applications in electronic devices, embarking on tackling

these challenges. "Just like the material for manufacturing silicon chips

is silicon single-crystal wafers, if you want to use graphene and other

carbon-based two-dimensional materials to achieve integrated electronic

devices, initiating a revolution in microelectronics technology, you must

prepare large size, high-quality graphene single-crystal wafers," said Wu

Tianru, Associate Researcher of the Institute.

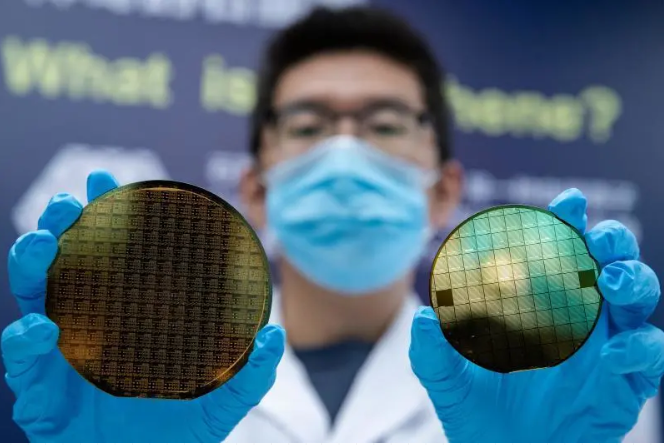

It can be said that after ten years

of hard work, with the support of major national scientific and technological

projects and Shanghai Science and Technology Innovation Action Plan projects,

the research team aimed at the high ground of high-quality graphene preparation

and high-performance device technology. They focused on the controllable

preparation of wafer-level graphene single crystals, concentrating on the

development and expansion of new functions and applications of graphene. From

growing monolayers to single crystals, and then to atomically flat large-area

wafers, Shanghai scientists have finally upgraded graphene from samples of a few

micrometers peeled off with tape to 8-inch wafers that can be produced on a

large scale.

To realize the mass production of

graphene wafers as soon as possible, the Shanghai Institute of Microsystem and

Information Technology, Chinese Academy of Sciences, signed an agreement with

the Shanghai Graphene Functional Platform last September, offering

cost-competitive industrial applications. Moreover, atomically thin graphene

materials can act as powerful sensors for various physical parameters (chemical

composition, humidity, temperature, strain, etc.). These single-chip sensing

platforms, combined with radio frequency identification antennas, can be used

as remotely readable detectors.

The small-batch production of

graphene wafers has laid the foundation for the research and development of a

new generation of domestic electronic devices. At present, some electronic

components based on graphene and used for data communication are undergoing

prototype demonstrations in the industry. Among them, electronic and photonic

components have been integrated into transmission systems and validated,

achieving high-speed, low-power data or telephone communications. The

optoelectronic modules of graphene photodetectors can detect the entire band

from visible light to thermal ranges. Under the CAS and China Electronics

Group, breakthroughs have been made in the core processes of graphene terahertz

detector devices, high-performance radio frequency transistors, and other

electronic devices using Shanghai research materials.

Article

transferred from WeChat Public Account "Shanghai Science and

Technology".